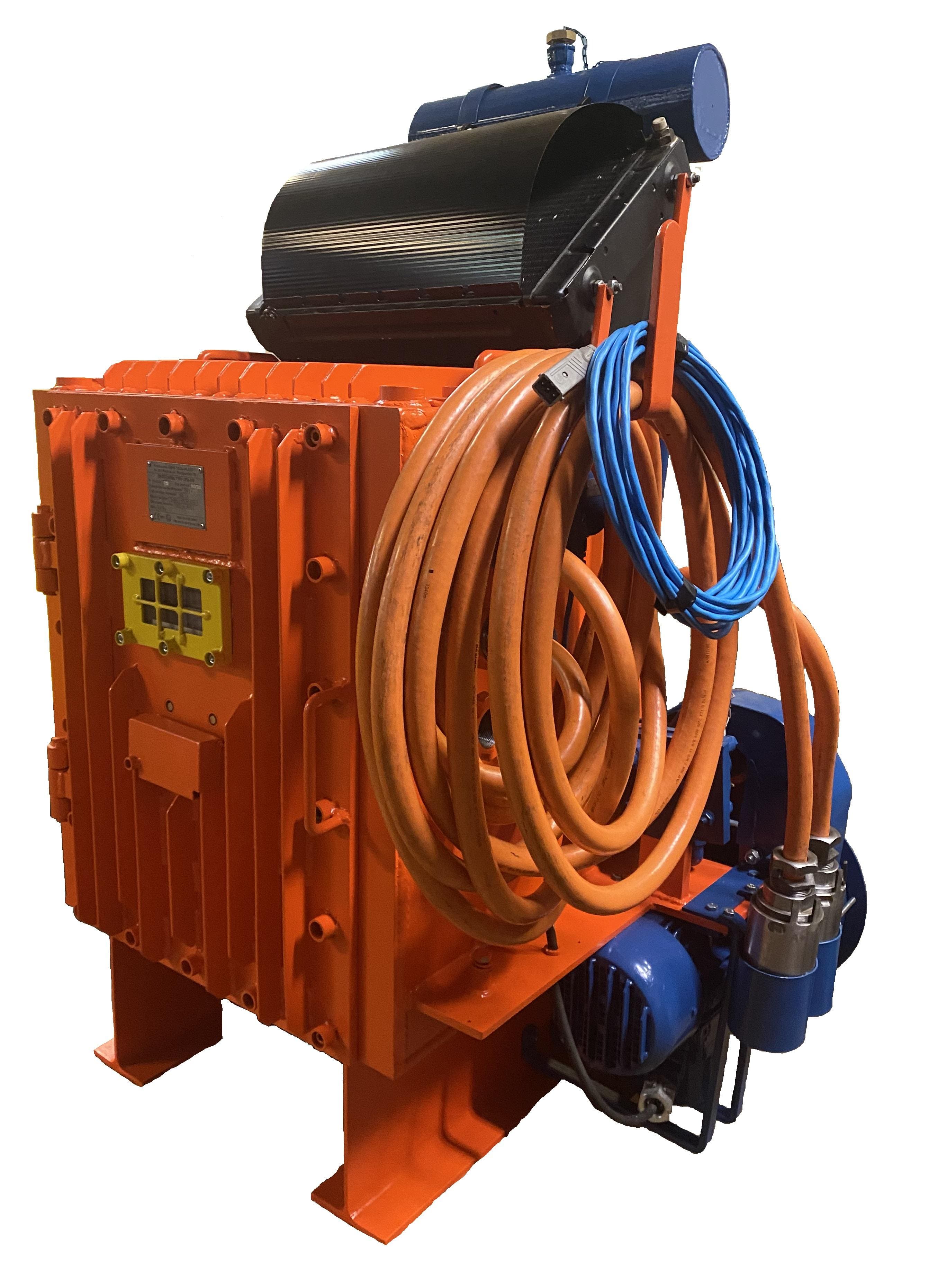

OPB-500 rectifier

Description

Application:

The OPB-500 rectifier is intended for charging the series of types of flameproof lithium-ion batteries of the SBS-4Lion type. The OPB-500 rectifier can be used in workings classified as “a”, “b” or “c” levels of methane explosion hazard and “A” or “B” levels of coal dust explosion risk in underground mines.

The OPB-500 rectifier consists of the following elements:

- Charger flameproof cover – 1 pc.,

- Elements of the passive and forced cooling system – 1 set.,

- Connection plugs with wires – 2 pcs.,,

- Control plug with cable – 1 pc.,

- Rectifier insert – 1 set

Technical specifications

OPB-500 rectifier

| Dimensions: | 850 x 910 x 1510 mm (width x depth x height.) |

| Mass: | 550 kg |

| Supply voltage: | 3x500V ±10% AC 50Hz |

| Nominal charging current: | 300A (for the supply voltage 3x500V) |

| Ambient temperature | -10oC to +40oC |

| Charging rated voltage: | 150V DC |

| Minimum charging voltage: | 110V DC |

| Maximum charging voltage: | 168V DC |

| Maximum temperature of external surfaces: | 50oC |

| Noise level: | 50 dB |

Construction of the OPB-500 rectifier

The OPB-500 rectifier is made as an explosion-proof casing in a “d” flameproof casing. Cover

the rectifier has the shape of a cuboid. The rectifier has a passive and forced cooling system.

Basic functions of the OPB-500 rectifier

Basic internal protections of the OPB-500 rectifier

threshold,

Certificate

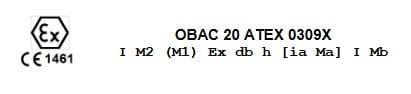

The OPB-500 rectifier has an EU-type examination certificate no .: OBAC20ATEX0309X of 27/08/2020 in accordance with the requirements of the ATEX Directive 2014/34 / EU of 26/02/2014, which was issued by the Center for Testing, Attestation and Certification OBAC Sp. z o. o. in Gliwice. The OPB-500 rectifier has the following marking:

The OPB-500 rectifier can be installed in rooms (zones) at risk of explosion in accordance with

as indicated above.

Project co-financed by European Funds

The company P.H.P.U. “Izol-Plast” Sp. z o. o. implemented a project financed by European Funds under the name:

“Conducting research and development works to develop an innovative product – a series of flameproof Li-Ion batteries for powering locomotives in underground mining plants with stored energy 105kWh and 150kWh”

The result of research and development works is a series of types of flameproof locomotive batteries in underground mining plants with stored energy of 105kWh and 150kWh.

The new product has been introduced to the offer of Izol-Plast.

Additional benefits from the implemented project

1.Avoiding the construction of battery holders at a given level of the mining plant:

- Avoidance of very large expenditures on the excavation of the battery compartment,

- Avoiding the construction of battery compartment equipment.

2. Removal of very harmful workplaces – maintenance of cargo holds with classic cells (with electrolyte):

- No gas build-up when charging from the SBS-4Lion battery.

3. The SBS-4Lion battery installed on the locomotive does not require any maintenance, e.g. adding electrolyte or distilled water.

4.Charging the SBS-4Lion type battery on the locomotive takes:

- for 700Ah battery – 2h 20 minutes,

- for 1000Ah battery – 3h 30 minutes.

5.OPB-500 rectifiers can be installed in workings classified as “a”, “b” or “c” degree of danger

methane explosion and the risk of coal dust explosion class “A” or “B”.

6. Baterie typu SBS-4Lion posiadają pełne zabezpieczenie przed:

- overheating,

- overcharging,

- too deep discharge.

7.SBS-4Lion batteries can be recharged in any state of charge.

8. The life of the SBS-4Lion type batteries is at least 5 times longer than that of classic or gel batteries.

with electrolyte.

9. The company P.H.P.U. “Izol-Plast” Sp. z o.o. has a technology of recycling used lithium-ion battery cells.

Download the catalog card: